AI's Transformative Impact on Manufacturing

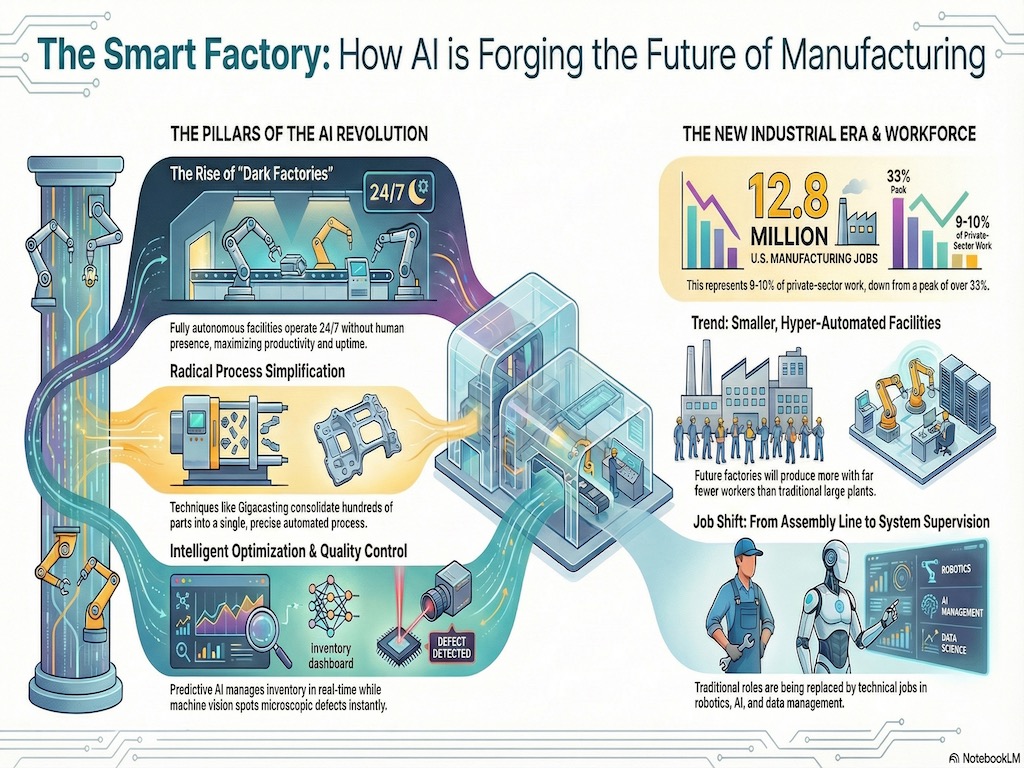

The confluence of AI and robotics is revolutionizing manufacturing paradigms, moving beyond mere incremental improvements to instigate disruptive change. This transformation is evident in the emergence of autonomous "dark factories," the radical simplification of production processes such as gigacasting, the optimization of inventory through predictive AI, and the rise of real-time quality control powered by intelligent vision. Together, these developments signal a fundamental shift in how goods are produced, how factories operate, and how entire supply chains function. The scale of the transformation is so significant that many people still underestimate how profoundly factories — and the jobs tied to them — may change.

Dark Factories: 24/7 Operation and Continuous Productivity

One of the most striking expressions of AI-driven manufacturing is the "dark factory" — a fully autonomous facility capable of operating without any on-site human presence. These factories run continuously, unconstrained by shift schedules, fatigue, or safety requirements that apply to human workers. The result is unprecedented productivity: uninterrupted operation, minimized downtime, and output levels unattainable through traditional manufacturing models.

As robotics, AI scheduling, and automated maintenance systems mature, dark factories are moving from experimental prototypes to practical industrial reality. Their rise forces a difficult societal question: if factories no longer require local labor, what happens to the towns and regions that have relied on manufacturing jobs for generations?

Manufacturing Process Simplification: Precision Through Radical Reduction

AI and robotics aren't just accelerating manufacturing — they are fundamentally simplifying it. Gigacasting, a technique pioneered in the automotive sector, demonstrates how hundreds of parts and steps can be consolidated into a single automated process. What once required welders, assemblers, inspectors, and multiple stations can now be executed by an automated casting system with extraordinary precision.

This simplification eliminates human error, reduces manual labor, and dramatically lowers production costs. Entire workflows that once depended on large teams of skilled workers can now be collapsed into streamlined, autonomous sequences. Such changes don't merely enhance efficiency — they redefine what a modern factory looks like and diminish the need for many traditional roles.

AI-Driven Inventory Optimization

Inventory management, long one of the most complicated challenges in manufacturing, is being reshaped by predictive AI. Modern systems analyze market demand, supplier behavior, transportation conditions, and historical patterns to orchestrate true just-in-time material delivery. Advanced platforms — including those deployed by companies like Palantir — enable factories to minimize excess stock while avoiding shortages.

This optimization reduces warehousing costs, improves capital efficiency, and creates a tightly synchronized supply chain that reacts dynamically to real-time conditions. When inventory becomes algorithmically optimized, the entire rhythm of manufacturing changes: production schedules align seamlessly with distribution, procurement, and logistics.

Quality Control and Defect Detection

Quality control is rapidly becoming one of the most AI-intensive domains in manufacturing. Machine-vision systems now perform inspections at speeds and resolutions far beyond human capability, identifying microscopic defects or structural anomalies before they escalate. These systems ensure consistent precision and dramatically reduce error rates.

More importantly, AI now oversees the health of production itself. Autonomous monitoring tools detect mechanical anomalies, operational irregularities, or emerging failure patterns — often correcting issues automatically or halting processes before they cause costly downtime. This creates a layer of reliability previously unattainable in human-dependent environments and allows factories to operate with minimal supervision.

A New Industrial Era — and the Future of U.S. Manufacturing

As of 2024, about 12.8 million Americans work in manufacturing, representing roughly 9–10% of private-sector employment — far below the mid-20th-century peak when the sector employed more than a third of U.S. workers. Although employment has stabilized in recent years, the industry is entering another profound transition as automation, robotics, and AI reshape factory operations. Instead of returning to large, labor-intensive plants, the U.S. is trending toward smaller, highly automated facilities that can operate nearly continuously and produce far more with far fewer workers.

Manufacturing is not disappearing, but the nature of the work is shifting dramatically. Traditional assembly-line roles are being replaced by technical positions in robotic maintenance, autonomous system supervision, advanced process control, machine-vision quality assurance, and data-driven supply-chain management. The challenge is whether workers can transition to these increasingly specialized roles quickly enough — and whether the gains from AI-enabled productivity will improve economic conditions broadly or concentrate among a small number of firms and highly skilled workers.